Are you crazy about carbonated drinks ? beverages that contain dissolved carbon dioxide gas, which creates bubbles and gives the drinks their characteristic fizziness.our machines are specifically designed to fill carbonated beverages, ensuring that the carbonation is maintained and that the filling process is efficient and sanitary. The sales team of G-packer and their engineers have a sharp insight into the demands of the customer base. Coupled with their 30 years of experience in the production of packaged beverages, they are capable of optimizing the existing packaging lines for customers while also taking into account the cost of new equipment. Ultimately, this ensures that our automated production lines can help customers achieve the expected results in a short period of time.

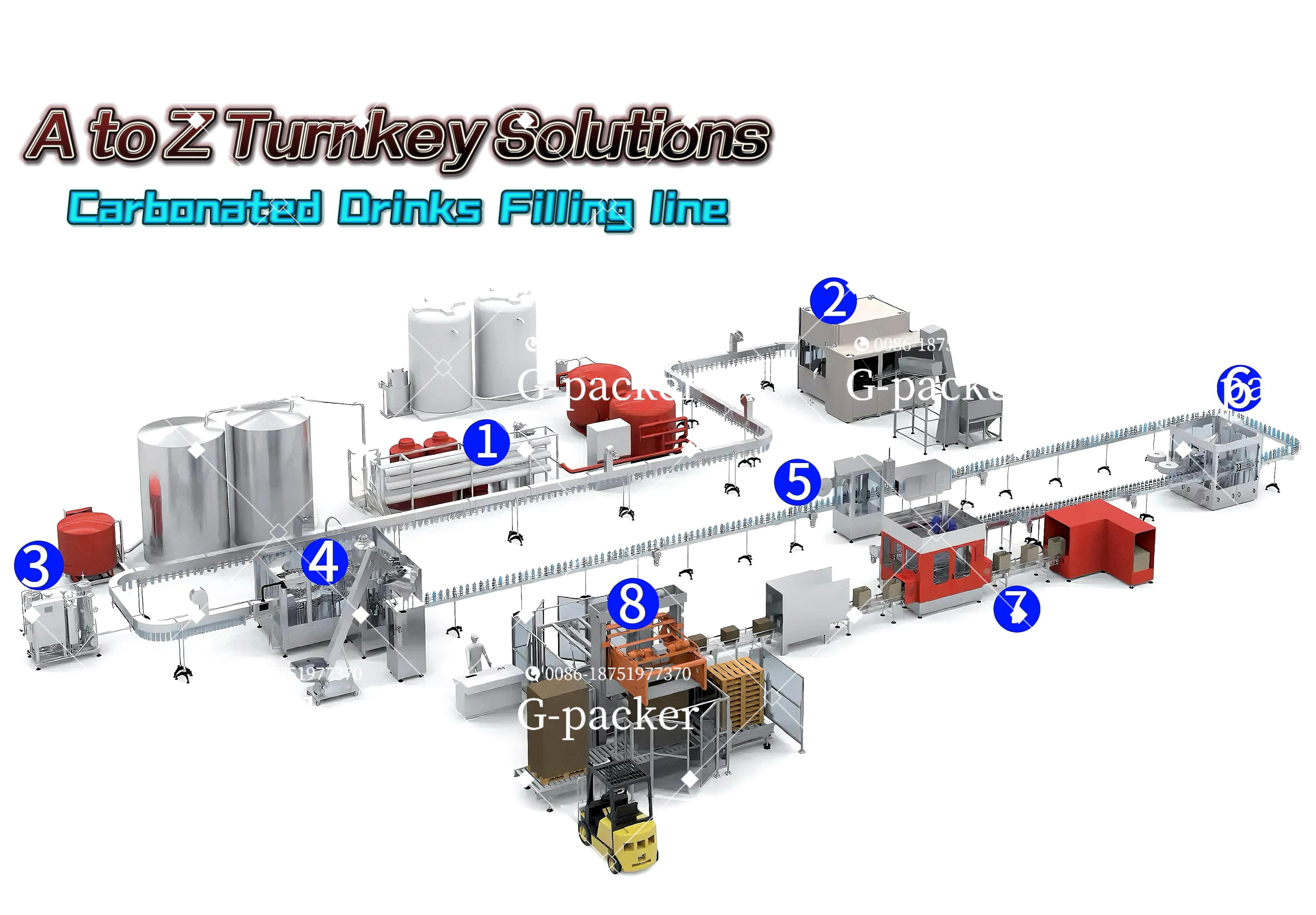

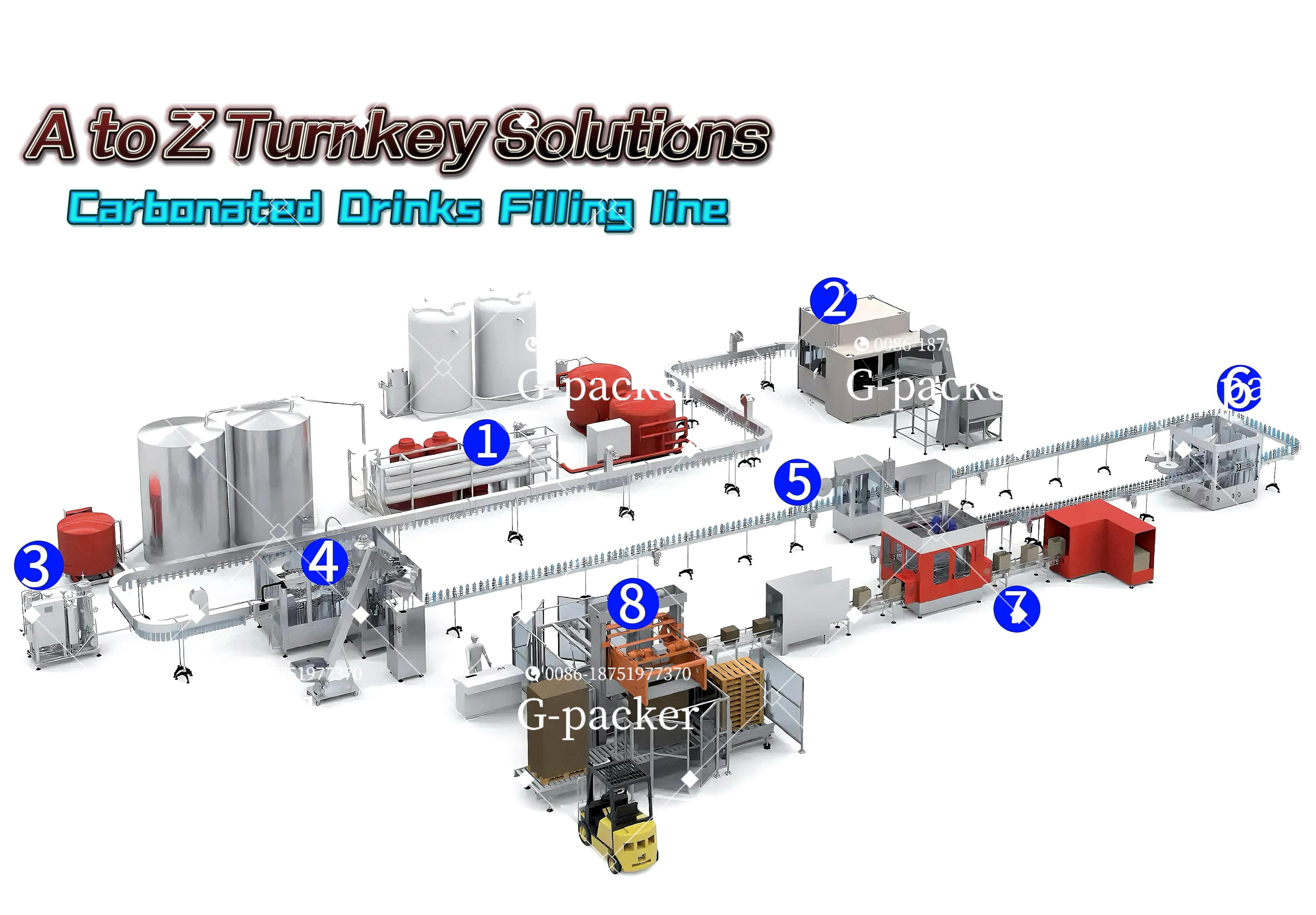

HOW TO INSTALL A CARBONATED DRINKS PRODUCTION LINE

Technical Parameter |

Model | CGF14-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 |

Capacity | 3000 | 5000 | 7000 | 10000 | 15000 | 18000 |

Bottle shapes | Round, Square or Other |

Bottle diameter | 50-115mm |

Bottle height | 160-320mm |

Compressor air | 0.3-0.7Mpa |

Rinsing pressure | >0.06Mpa <0.2Mpa |

Application | Hot Juice Filling line |

Motor power | 2.2kW | 3.5kW | 4.5kW | 6kW | 7.5kW | 9.5kW |

Weight | 2800kg | 3650kg | 4800kg | 6800kg | 8500kg | 10000kg |

What are you waiting for?Fill out the form and let us contact you, or contact us directly for more details.